Source: https://unsplash.com/photos/jHZ70nRk7Ns

Every business, from automobile industries to high-tech manufacturing industries, is now compelled to use digital technology to transform factory operations. However, doing so effectively can be difficult.

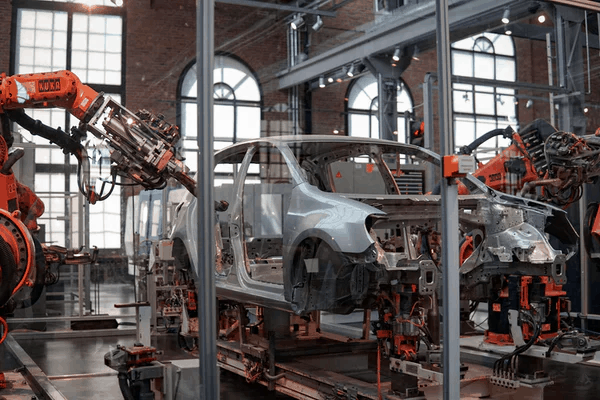

The automotive industry is no stranger to automation. Unlike previous generations of factories, which have concentrated on discrete operational changes, the factory of the future will be designed around completely intelligent and connected devices. This system can easily learn and adapt to new and evolving demands thanks to a continuous stream of data from market, operational, and production applications, resulting in a truly smart factory.

This article aims to inform you of the trends that have been actively fueling changes in the manufacturing industry, as well as those that have been holding it back. These trends determine the outcome of the products you consume or retail. Read on to find out more.

Trends Fueling the Revolution

Source: https://unsplash.com/photos/4F_EBY__6II

360° Visibility Around Corners

Companies can now build and test scenarios in the virtual environment, simulating the design process and assembly line before creating an actual product, thanks to new tools. Simulating the product-creation step reduces production time and ensures that the manufacturing process produces exactly what the company expected.

1. Three Dimension View

3-D printing, which allows for the seamless production of tangible objects using a single computer, is also creating waves in the manufacturing sector. This is a significant change because it expands the number of ways you can model parts.

In certain cases, where six parts would usually be needed, 3-D printing will achieve the same result in one piece without any need for additional processes such as welding or screwing. Three-dimensional printing saves time and money by recycling and reusing plastic waste hence reducing the need for replacements and transportation.

2. Autonomous Advanced Manufacturing

Another important part of the industry’s future is automation. Also in conditions that would be deemed harmful for humans, automation allows for a degree of precision and efficiency unattainable by humans. With features like image and speech recognition to re-create complicated human tasks, the newest iteration of robots is not only easier to program, but also to use.

Simply put, manufacturers can produce highly accurate products that coil even help other manufacturers do the same. A good example is the petroleum refinery, which requires industrial parts such as pipes from other manufacturers.

3. Factories and the Cloud

Smart sensors can translate data into different systems of measurement, communicate with other machines, collect statistics and feedback, and turn off devices if there is a safety or performance problem. Companies may use cloud computing to collect and analyze data that affect the manufacturing process.

Using the refinery example above, the factory can now collect fault data from the cloud and determine what and when they need to replace parts of their factory.

4. Human-Managed Robots

Although there are still some serious challenges yet, including the obvious concern about robots displacing workers, the outlook is positive. The majority of automation is often used for tasks that are dangerous or difficult for humans to perform. As a result, robots are a supplement to, rather than a substitute for, human staff. We will be able to increase our productivity thanks to robots.

Trends Holding Back the Evolution

Source: https://unsplash.com/photos/WjOWazUPAss

1. Digitization of the Supply Chain

Many companies have begun to introduce smart factory instruments in areas such as planning and maintenance, especially in the automotive industry. However, the smart factory must go beyond the factory floor, integrating with suppliers and consumers beyond the four walls.

The supply chain network is evolving from a sequential, linear operation to an integrated, transparent, and multi-layered ecosystem of trade relations as a result of digitization. To achieve real success, manufacturers must understand how to incorporate their smart manufacturing into these new digital supply chains.

2. Monetizing Data

The smart factory will be data-driven. Data can direct each process, identify any operational mistakes, deliver user input, and enhance both the quality and volume of performance using advanced analytics and AI. Consider an automobile manufacturer’s future.

Data that recognizes demand, minimize the downtime required for retooling and reconfiguring, and enables the ‘run of one’ can allow even more customization in factories. As a result, manufacturers will be able to consider how to use their data to develop current evidence products and services, such as predictive maintenance applications in connected cars.

3. Transformation To the Digital age

To others, the term “digital transformation” refers to the conversion of paper-based systems to digital ones. This is taken a step further in the smart factory. The integration of operations and information technology is at the heart of this transition, which is fueled in part by the exponential growth of IoT.

Every element of factory operations can be linked and controlled thanks to this integration. IoT data is used in a variety of ways, including feeding into operating systems to increase efficiency or mixing with data from other business systems to begin improving how the factory and supply chain work.

4. Widening Skills Gap

People, not technology, are the secret to an effective digital migration. This is especially true when it comes to potential smart factories. Although increased digitalization is unlikely to result in a reduction in headcount, workers’ roles and duties will shift as processes and information technology become more tightly integrated.

Conclusion

The digital revolution, the factories of the future, Artificial Intelligence, and automation, in general, are all words we need to look out for in this current industrial evolution. The good side is that industries get safer for human workers and products get better for consumers.

As a manufacturer, your transition into the digital age will require you to have savvy equipment and tools. One of the products with multiple applications is the kf trunnion ball valve; a smartly designed product that will ensure accurate fluid control for the factories of the future. This product has applications in LNG, petroleum, hydrocarbon, petrochemical, and other chemical industries.